Precision CNC Milled Components Manufacturer

Precision Milled Components Mumbai, India | CNC Milled Components, Bucket Mould Machining, Sheet Metal Die Part, Insert Machining, Automobile Components, Manufacturer & Exporter in UAE, Qatar, Saudi Arabia, Qatar, Russia, Nigeria.

Precision Milled Components, Milled Components using CNC, CNC Milled turned parts, Anchor Bolt, Rocker Plate, Flanges For Rotating Tubes Leading Supplier & Trader which are available at different sizes, material and specification as per requirement.

Different apparatuses are intended to help the generation and hence lessening the setting time and cost of the segment. Different Ferrous, Non-ferrous and colorful material are utilized as a part of generation of these exceedingly exact CNC processed segments. Last Inspection is done on CMM for giving exceptionally exact segment to our clients.

We are among the few ISO 9001:2008 enrolled organizations for exactness turned parts. Indian Factories, Small Scale Manufacturers, and Automotive Parts Suppliers all over Mumbai and India believe our quality, and we guarantee finish return on ANY imperfect supplies!

Manufacturers in India's quick creating economy require the best plant extras; and it has the assets and the innovation to supply processing plant extras and turned parts for a wide range of foreign and household made mechanical machines and vehicles.

Precision Milled Components mumbai, Precision Milled manufacturer mumbai, CNC auto parts, manufacturers, suppliers, exporters, traders, dealers, manufacturing companies, retailers, producers in india, OEM Supplier of Bucket Mould Machining, Sheet Metal Die Part, Insert Machining, Automobile Components, Crate Mould Machining, Anchor Bolt, Rocker Plate, Flanges For Rotating Tubes.

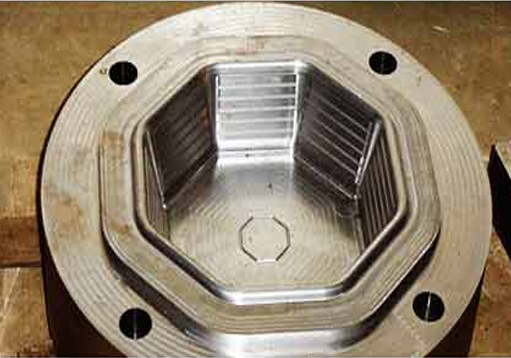

Our organization is enrolled among first class producers of a broad scope of Bucket Mould Machining CNC Components. These Bucket Mould Machining CNC Components are designed at our propelled creation office under the supervision of modern specialists. Bucket Mould Machining CNC Components are broadly requested by the customers because of their unmatched quality, exact measurements and sturdiness. We offer Bucket Mould Machining CNC Components in different shapes and sizes, which make it less demanding for the customer to make the last choice. The innovative perfection of our experts empowers us to offer a brilliant product offering to the customers. Other than cutting edge advancements, we guarantee that finest crude materials are consolidated in the creation procedure. Our quality reviewers watch out for every one of the phases of generation, which keeps away from event of assembling deformities in the last Bucket Mould Machining CNC Components run. We have set up solid relationship with presumed sellers of the business. Consequently, we source high review crude materials from them and in this way, totally ensure the nature of our items. We have a solid coordinations arrange that empowers us to convey items to the customers' end inside the stipulated time span. In addition, we give altered planning and bundling office to our esteemed customers. Throughout the years, our organization has gained a wide customer base, attributable to aggregate quality administration and aggressive estimating framework.

Features

Precision engineered

Long service life

High tensile strength

Sheet Metal Die Part are thrown parts utilized as a part of the bite the dust fabricating in sheet metal industry. They are machined according to the outlines and models given by client. All the required parameters are held upto the check in order to help in getting the last Sheet Metal Die Part as fancied. Sheet Metal Die Part are all uniquely crafted parts which require an exceptionally solid specialized group having a decent comprehension of the uses of the occupation and in addition the get together.

Chair Insert Machining are high combination steel parts utilized as a part of the plastic shape industry. Chair Insert Machining have accuracy processed parts are for the seat embeds. Chair Insert Machining are tradable parts so most extreme administer to keeping up its measurements. The examples utilized as a part of the supplements are exceptionally basic and different little nose range carbide ball end plants are utilized to accomplish the same.

Automobile CNC Components accuracy processed parts are utilized for prototyping in vehicle industry for R&D and advancement period of any plastic segment. Our vehicle parts are exceptionally acclaimed for its high sturdiness and rough development. Automobile CNC Components are manufactured in congruity with worldwide quality norms.

Crate Mould Machining CNC Components are high compound steel parts utilized as a part of the plastic form industry. Crate Mould Machining CNC Components exactness processed segments are for the seat embeds. Crate Mould Machining CNC Components are tradable parts so most extreme watch over keeping up its measurements. The examples utilized as a part of the supplements are extremely basic and different little nose span carbide ball end factories are utilized to accomplish the same.

Features

High-end finish

High quality

Corrosion Resistance

Reliability

Durability

We create a wide extent of Anchor Bolt CNC Components that is generally requested in the business for vigorous development and high quality. Our scope of Anchor Bolt CNC Components is created utilizing quality endorsed materials that our acquisition specialists source from the most dependable and genuine sellers of the business. We take after endorsed modern guidelines in our assembling procedure, so as to convey world-class Anchor Bolt CNC Components to our regarded customers. We have procured skilled experts in our group, who have quite a while of modern experience. Our generation architects are knowledgeable with the complexities of creation process and attempt to convey Anchor Bolt CNC Components that precisely meet the requests of customers in each perspective. We have a group of value controllers, who help us in showing a scope of faultless stay dashes in the market. These specialists are watchful in the whole generation process and do different stringent tests on the Anchor Bolt CNC Components at every stage, keeping in mind the end goal to guarantee most extreme advantages to the customers. We offer these Anchor Bolt CNC Components in shifted sizes and determinations according to the exact needs and requests of the customers. One can benefit these Anchor Bolt CNC Components from us at aggressive costs. In addition, we convey these Anchor Bolt CNC Components to the doorsteps of our customer inside the conferred time span.

Features

Anti-corrosive finish

Application specific design

Durable

We offer exactness built Rocker Plate CNC Components that are utilized as a part of conjunction with Rockers Shafts. Rocker Plate CNC Components is a gear utilized as a part of shipbuilding industry. The material utilized for development is SS316/1.4401 steel review. Our Rocker Plate CNC Components are machined on CNC machines and kept up for shut resistances. Our parts are machined on CNC machines with legitimate process and different aligned instruments. Advance, these are machined on a Vertical Machining Center therefore giving the required geometrical and dimensional correctnesses. Additionally, these are tried on different parameters of value to give finish consumer loyalty. Aside from this we additionally offer customization office to our customers. We give them Rocker Plate CNC Components as indicated by their prerequisites at sensible costs.

Features

High-end finish

High quality

Corrosion Resistance

Reliability

Durability

Our significant experience and cutting edge producing offices empowers us to exhibit an exceedingly dependable scope of Flanges For Rotating Tube in the market. These Flanges For Rotating Tube are the principal decision of different customers having a place from various mechanical foundations for unrivaled quality and ideal execution. We consolidate high-review materials in our generation procedure, which are sourced from solid and genuine sellers of the market, who ensure their provisions. Remembering the variegated needs and requests of the customers, we offer these Flanges For Rotating Tube according to their particular needs and requests. Our creation engineers utilize propelled generation approachs to outline and build up the range to deliver a scope of world-class items. We have a group of value controllers, who help us build up a product offering that is in entire consistence with recommended modern models. We entirely check our range on all around characterized parameters before the last conveyance to the customers, keeping in mind the end goal to guarantee greatest advantages to them. We are upheld by an extensive stockroom office, which encourages us to stock our Flanges For Rotating Tube in a protected situation. Our bundling specialists lay an extraordinary accentuation on pressing these Flanges For Rotating Tube in most defensive materials, keeping in mind the end goal to guarantee safe conveyance of Flanges For Rotating Tube to the customers. One can profits these items from us at industry driving costs.

Features

High tensile strength

Precisely engineered

Long service life

Exports for Precision CNC Milled Components

Metal Ministry inc. exports Precision CNC Milled Components in various countries like India, Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Spain, France, United Kingdom, Indonesia, Israel, Iran, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Russia, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia.

Metal Ministry inc. exports Precision CNC Milled Components in various cities like Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, Howrah, Sydney, Ahvaz, Karachi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo.

If you have any enquiries related to Precision CNC Milled Components feel free to get back to us on :- Telephone : +91-22-66109947 / +919892171042, Email : enquiry@metalministry.in